Tile floors can be restored, much like furniture and other items, not in the same way but with the same care and perseverance, which requires to restore a genuine piece of art. Tile floor polishing can be completely refurbished while preserving their original components, but it takes perseverance and your best artwork.

Like other coatings, tile floor polishing deteriorates with time and loses color, but they are particularly vulnerable to oil stains, old waxes, rust, or burns from cleaning with strippers or etching. As a result of forgetting, they are also susceptible to breaking and potential chipping.

Restructure a ceramic tile

Depending on the condition of the ground, the recovery project may be more or less challenging. In the case of a free or damaged tile, we only need to replace it with a similar one. However, if there is general damage or deterioration, such as if we are remodeling a historic home but want to preserve the original ground, we will need to replace all of the ceramic components.

This task can be finished on the floor or, with more perseverance and effort, by removing each tile individually so it can heal before being replaced.

When working on the floor, the first thing we must do is remove the broken or chipped pieces using a chisel. If we decide against upgrading them since it’s impossible to get an exact part, we can try to restore them using putty, sanding, and paint.

After being repaired, the damaged component is replaced in its original spot using cement or mortar. The extra product is then cleaned using newspaper. The pavement’s relaxation is reinstated once all of the recently laid tiles have dried.

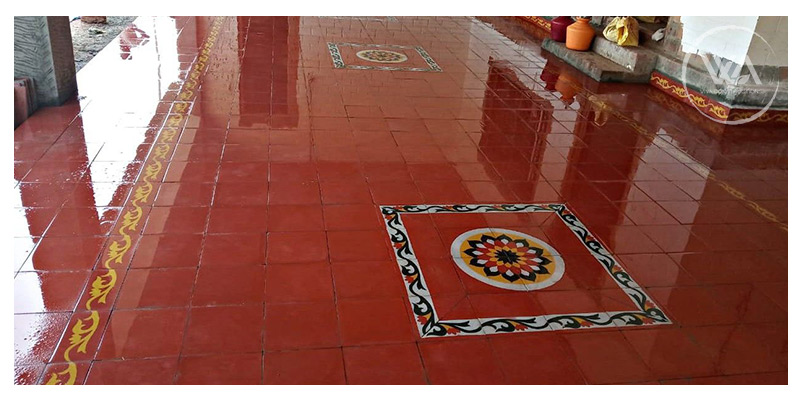

Tile floor polishing

The most popular technique is polishing. By the wear and tear of the distinct zones, the ground is polished using drag plates equipped with segments of different grains.

Resin or diluted aluminum fluorosilicate is used to polish the ground; the latter is simpler to obtain and employ. Its surface is made of satin or a smooth finish with these products, giving it a more pleasant, durable touch and bringing out the colors.

The chosen shine will appear after adding a glaze. Once the ground is dry and free of the remnants of the prior product, waterproofing is made in contact to assure its preservation.

Before applying the shine and waterproofing products, you may need to paint the floor with the proper paints if you want to give it a fresh coat of color. Before painting, a synthetic sealer is applied to help it cling to the paint properly; however, after tile floor polishing, it frequently grips more firmly. Tiles respond nicely to coatings made of epoxy.

A foam curler or a large brush can be used for the application, depending on the amount of time and commitment you have to devote to the task.

In jobs where rehabilitation with the proper concentration, the tiles are removed one at a time and placed through this process independently with great persistence. Chips are fixed, polished, painted, and guarded one at a time before being reinstalled on a ground that has been totally and wonderfully restored, like new, while maintaining its records and provenance.